Casting is a very important step in the jewellery-making process, where molten metal is poured into moulds to create exquisite designs. Casting machines help streamline this process, ensuring precision and efficiency. If you’re looking to improve your skills, understanding how casting machines work, can take your craft to the next level. In this update, we’ll break down the basics of casting machines and provide useful tips to make the most of this essential machine.

What is Jewellery Casting?

Jewellery casting involves melting metal, such as gold, silver, and pouring it into a mould to create a desired shape. It’s used to produce intricate and detailed jewellery pieces, from rings to necklaces. Casting machines simplify this process, providing consistent results, better control, and higher-quality pieces.

How Casting Machines Work?

Casting machines use high heat to melt metal and then transfer it into moulds. There are different types of casting machines depending on the method you prefer. Here’s a look at the process:

- Preparation: The first step is preparing the mould. The mould can be made of a variety of materials, including plaster or sand, depending on the casting technique being used.

- Melting the Metal: The metal is placed into a crucible inside the casting machine. The machine heats the metal to its melting point, making it flow like liquid.

- Pouring the Metal: Once the metal is molten, it’s carefully poured into the prepared mould. Many casting machines are designed with a vacuum or pressure system that helps the metal flow into every detail of the mould, ensuring high precision.

- Cooling: After the molten metal is poured into the mould, it cools and hardens, taking the shape of the mould.

- Finishing Touches: Once the casting has cooled, the mould is removed, and the piece is cleaned, polished, and finished to the desired look.

Benefits of Using Casting Machines

You can gain the following advantages after choosing the right Casting Machine for your production!

- Precision: Casting machines provide precise control over the temperature and metal flow, ensuring fine details are captured in the mould.

- Efficiency: Casting machines speed up the process of creating multiple identical pieces, reducing the time spent on each piece.

- Consistency: With a casting machine, you can repeat the same process to create multiple high-quality pieces with minimal variation.

- Versatility: Casting machines can be used for various metals, including gold, silver, and brass, making them versatile for different jewellery projects.

Choosing the Right Casting Machine for Your Needs

When selecting a jewellery casting machine, consider the following:

- Size and Capacity: Determine how much metal you need to melt at once and choose a machine with the appropriate capacity.

- Method: Different casting methods (such as centrifugal, vacuum, or pressure casting) have different benefits. Choose a machine that suits the technique you want to use.

- Material Compatibility: Ensure the machine can handle the types of metals you plan to cast, whether they’re low-melting alloys or high-temperature metals like platinum.

- Ease of Use: Look for machines with user-friendly controls that allow for consistent results.

Tips for Successful Casting

- Proper Mould Preparation: Ensure your mould is clean and free from debris to avoid imperfections in the casting.

- Control the Temperature: Overheating or underheating the metal can affect the final result. Use a thermometer and follow the recommended temperature for each metal.

- Use the Right Metal: Choose the appropriate alloy for your design to ensure the best quality and durability of your jewellery.

- Handle with Care: Always handle molten metal with care, wearing appropriate protective gear, including gloves, safety goggles, and a protective apron.

Final Thoughts

Casting machines are a valuable investment for jewellers who want to achieve high-quality, consistent results with ease. By understanding the process and choosing the right equipment, you can enhance your jewellery-making process, reduce production time, and create pieces that showcase quality of work.

Jewel System & Services : Your Partner in Jewellery Casting

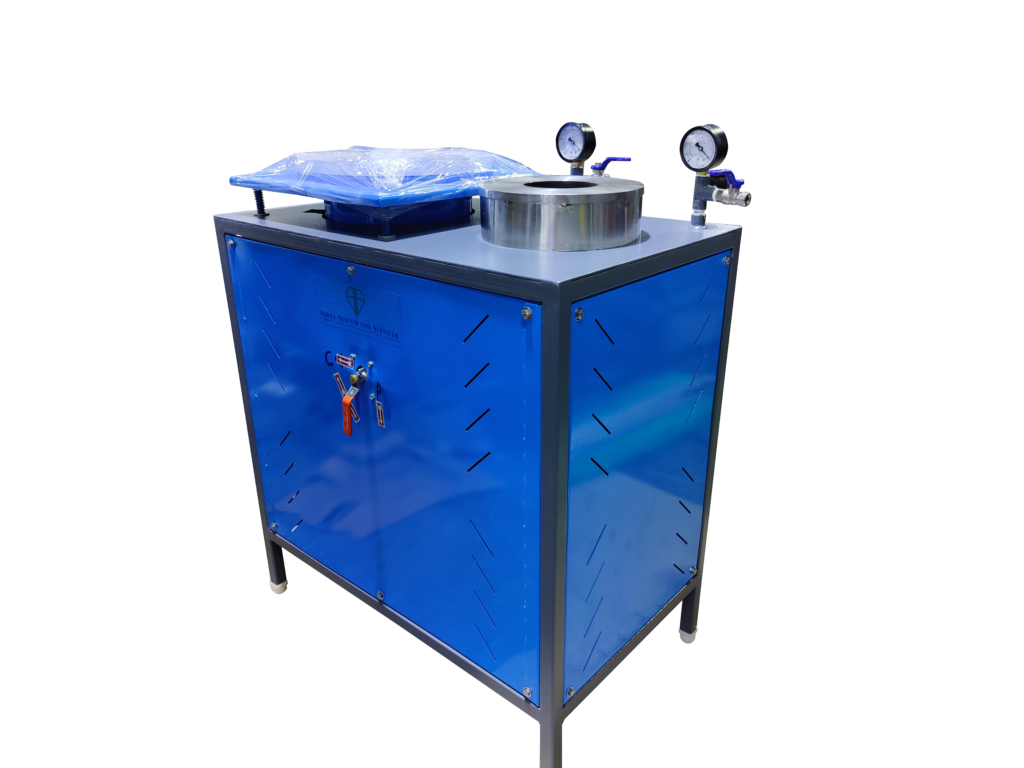

At Jewel System & Services, we offer a wide range of high-quality Casting Machines designed to help you create intricate and professional jewellery pieces. Whether you’re working with gold, silver or brass, our casting machines deliver precision, durability, and efficiency.

Visit Jewel System & Services today to browse our extensive selection and uplift your jewellery-making experience.