Polishing Machine is being used to polish jewellery which is a crucial step in jewellery-making process. Whether you’re working with gold, silver, or other precious metals, achieving a high-luster finish is essential for making your jewellery pieces stand out. Polishing machines have revolutionised this process, making it quicker, more efficient, and more consistent. These machines can help you achieve a flawless, professional-quality shine that manual polishing simply can’t match.

In this post, we’ll explore the importance of polishing machines, how they work, and the best practices to get the best results.

Why Polishing Machines Are Essential for Jewellery Makers?

Polishing machines are designed to deliver consistent, high-quality finishes on jewellery pieces, ensuring that each item looks polished and pristine. The polishing process is vital for several reasons:

- Enhances Appearance: Polishing removes imperfections and smoothens the surface of the jewellery, enhancing its overall appearance. This step is especially important for intricate designs where small imperfections can detract from the piece’s beauty.

- Boosts Durability: A smooth, polished surface is less prone to scratches, tarnish, and corrosion, which helps maintain the jewellery’s appearance and extends its lifespan.

- Saves Time: Polishing machines allow for faster, more efficient polishing, especially when dealing with large quantities of jewellery. They are designed to handle repetitive tasks and can be used to polish multiple pieces at once.

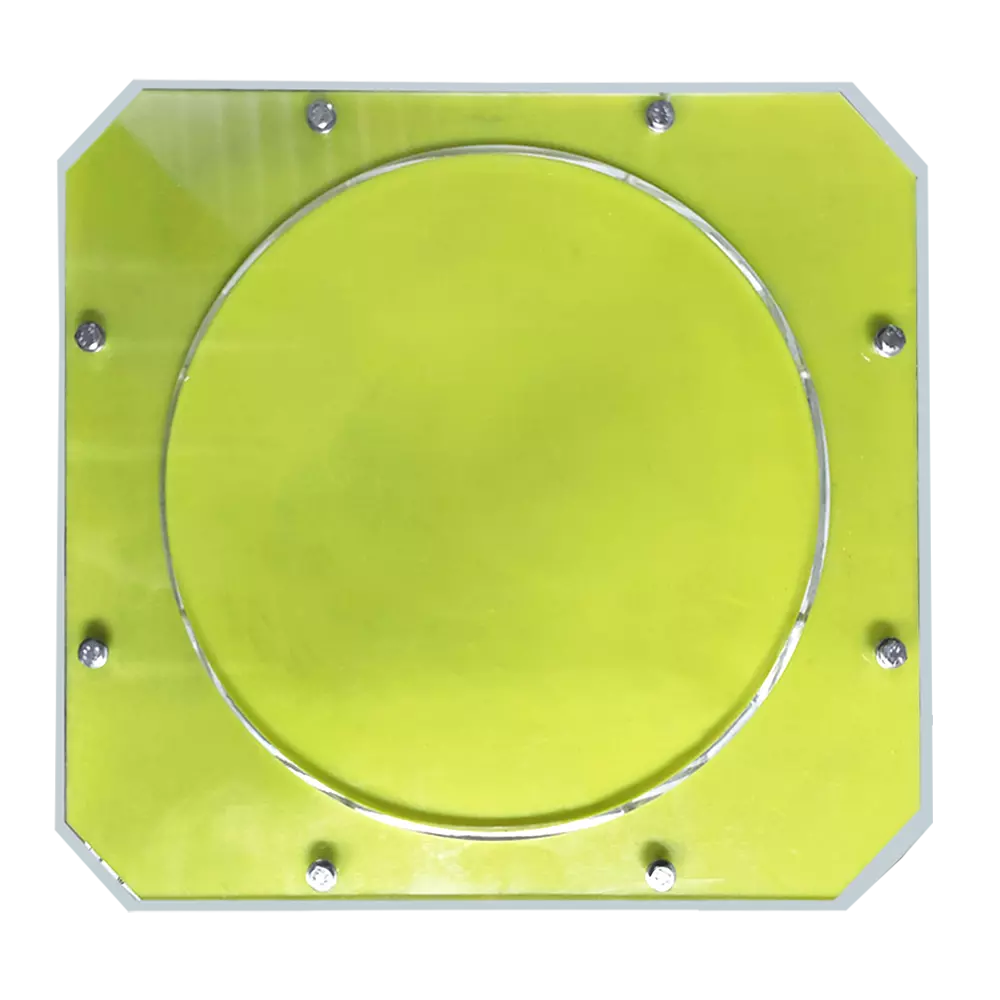

Magnetic Polishing Machines

When selecting a polishing machine for your jewellery-making business, it’s essential to choose one that fits your specific needs. One of the most effective types of polishing machines for achieving high-quality finishes is the Magnetic Polisher.

1. Magnetic Polisher: This type of polishing machine uses magnetic fields to agitate the jewellery pieces in a polishing solution. Magnetic polishers are perfect for achieving a smooth, high-luster finish on intricate designs and delicate components. The magnetic action ensures that the jewellery is polished gently but effectively, reducing the risk of damage to delicate pieces. This makes it an ideal choice for professionals working with small, intricate, or delicate jewellery pieces such as rings with stones or finely detailed pendants.

Best Practices for Polishing Jewellery

To achieve the best results with your polishing machine, follow these best practices:

- Choose the Right Polishing Compound: The type of polishing compound you use plays a crucial role in the final finish. For gold and silver, rouges are ideal, while tripoli compounds work well for harder metals. Selecting the correct compound helps you achieve the desired shine and smoothness.

- Use the Correct Buffing Wheel: Buffing wheels come in various materials and stiffness. Soft cloth wheels work best for delicate metals, while harder wheels are better suited for polishing tougher metals. Match the wheel to the metal you’re polishing for optimal results.

- Maintain Consistent Pressure: Apply even pressure while polishing to avoid damaging the jewellery. Too much pressure can cause scratches or even deform the piece. Be gentle and consistent to achieve a smooth finish.

- Clean Jewellery Before Polishing: Ensure your jewellery pieces are free from dust, dirt, or oils before placing them in the polishing machine. Clean jewellery will polish more evenly and efficiently.

- Control the Temperature: Overheating can cause damage to delicate metals. Ensure the polishing machine doesn’t overheat the pieces by controlling the time and speed of the process.

- Regular Maintenance of Polishing Machines: Keep your polishing machines in top condition by cleaning and maintaining them regularly. Worn-out buffing wheels or dirty polishing machines can lead to uneven finishes.

Benefits of Polishing Machines in Jewellery Production

Investing in a high-quality polishing machine offers several benefits to jewellery makers:

- Precision and Consistency: Polishing machines offer precision, ensuring that every piece of jewellery receives the same level of finish. This consistency is especially important for businesses that produce multiple identical pieces.

- Increased Productivity: With polishing machines, jewellers can polish large quantities of pieces in less time, increasing overall productivity and enabling them to meet growing demands.

- Cost-Effectiveness: While the initial investment in a polishing machine may be higher, the increased efficiency and speed of production can save time and money in the long run.

Choosing the Right Polishing Machine for Your Needs

When selecting a polishing machine, consider the following:

- Type of Jewellery: What kind of jewellery do you primarily create? For delicate or intricate pieces, the Magnetic Polisher is ideal as it offers a gentle, high-quality finish without causing damage.

- Production Volume: If you’re polishing large quantities of smaller or delicate items, a magnetic polisher can handle the job efficiently, allowing for uniform results.

- Size and Space: Consider the available space in your workshop. Magnetic polishers are typically compact and can fit into most workspaces with ease.

Final Thoughts

Polishing machines are an essential tool for jewellery makers looking to achieve high-luster finishes with consistency and efficiency. By understanding how to use these machines effectively, you can enhance the appearance and durability of your jewellery, increase productivity, and reduce time spent on manual polishing. The Magnetic Polisher stands out as an ideal solution for achieving a professional, smooth finish on delicate and intricate pieces.

Jewel System and Services’ Polishing Machine: Precision and Excellence in Every Finish

Jewel System and Services offers top-of-the-line polishing machines designed to deliver exceptional results for jewellery makers. Whether you’re polishing intricate designs, delicate stones, or larger pieces, their polishing machines ensure a high-luster finish with precision and consistency. Known for their durability and innovative features, these machines are engineered to meet the unique needs of jewellery professionals, helping them achieve flawless, professional-grade polishing every time.

One of the standout features of Jewel System and Services’ polishing machines is their ability to handle a wide range of jewellery types. From gold and silver to more complex alloys, these machines provide the versatility required to polish different materials to perfection. The efficient design allows for high productivity, making it an ideal choice for both small-scale and large-scale production .

Moreover, Jewel System and Services’ polishing machines are built with ease of use in mind. With user-friendly controls, these machines are designed for jewellers of all skill levels, offering a seamless polishing experience. They are also easy to maintain, ensuring that your investment remains in top condition over the long term.

For jewellers seeking to enhance the shine and smoothness of their pieces, Jewel System and Services’ polishing machines provide the perfect solution. With cutting-edge technology and reliable performance, they help jewellers bring out the best in every piece, ensuring that every item not only looks spectacular but also retains its quality for years to come.

Boost your jewellery creations with Jewel System and Services’ advanced polishing machines—contact us today for more details!